GelSight’s tactile 3D imaging enables high-precision, non-destructive surface inspection on any material—metal, composites, polymers, and more. Its portable technology rapidly detects cracks, corrosion, and surface wear in aerospace, defense, and industrial MRO. 1-touch PDF reporting ensures seamless compliance, traceability, and digital documentation.

Defect Measurement

on Engine MRO

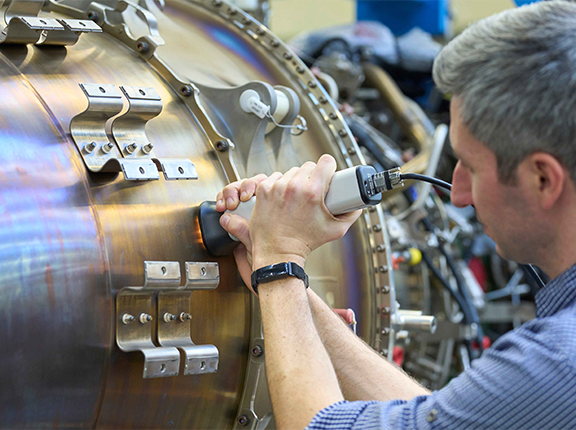

GelSight’s technology is highly effective for defect measurement in engine Maintenance, Repair, and Overhaul (MRO) due to its precise surface imaging capabilities. With its elastomeric sensor, GelSight can capture ultra-high-resolution, 3D surface details, allowing for accurate identification of small defects, scratches, and corrosion on complex engine parts. GelSight empowers MRO technicians to make data-driven maintenance decisions, reducing downtime and improving engine reliability.

Defect Measurement

on Engine MRO

GelSight’s technology is highly effective for defect measurement in engine Maintenance, Repair, and Overhaul (MRO) due to its precise surface imaging capabilities. With its elastomeric sensor, GelSight can capture ultra-high-resolution, 3D surface details, allowing for accurate identification of small defects, scratches, and corrosion on complex engine parts. GelSight empowers MRO technicians to make data-driven maintenance decisions, reducing downtime and improving engine reliability.

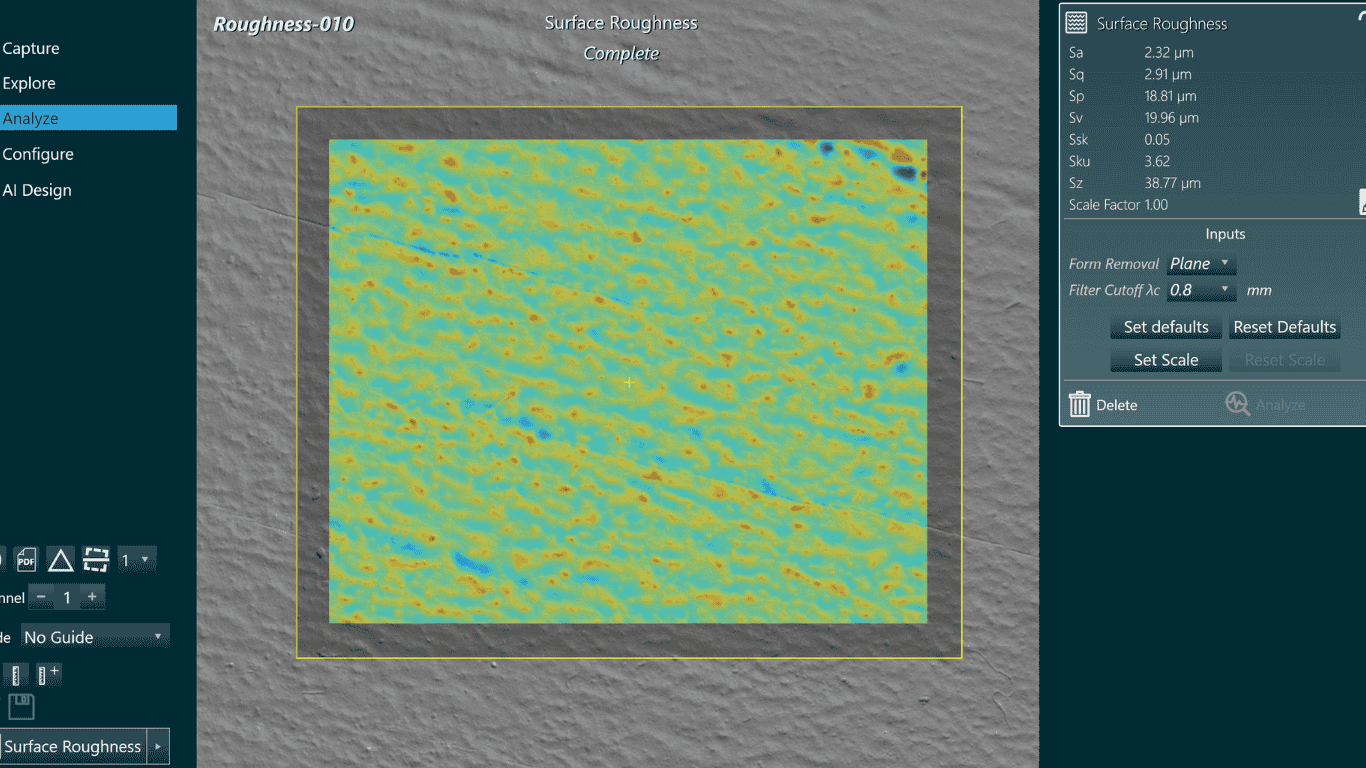

Roughness on Landing Gear

GelSight is ideal for measuring surface roughness on landing gear, ensuring these critical components meet safety and performance standards. The elastomeric sensor captures detailed 3D images of the landing gear surfaces, allowing technicians to precisely assess roughness levels, machining quality and and detect any wear, pitting, or other surface issues in MRO environments.

Roughness on Landing Gear

GelSight is ideal for measuring surface roughness on landing gear, ensuring these critical components meet safety and performance standards. The elastomeric sensor captures detailed 3D images of the landing gear surfaces, allowing technicians to precisely assess roughness levels, machining quality and and detect any wear, pitting, or other surface issues in MRO environments.

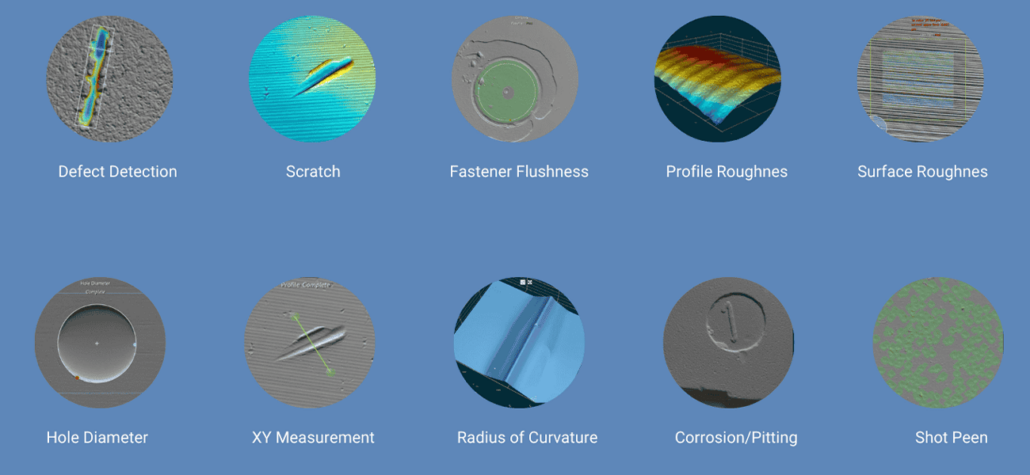

Airframe Defects and

Fasteners

GelSight’s non-destructive inspection approach ensures that no damage occurs to the airframe, while GelSight’s portability allows for quick checks directly on the aircraft’s sensitive parts. By providing fast, consistent data, GelSight enhances inspection efficiency of holes, fasteners, gaps, defects and more, supporting quality control and safety in aircraft assembly and maintenance on any material.